Projects

|

This page outlines a number of projects that I have led over the years. I have included both professional and personal projects that were of particular significance to me. In the sections below are brief descriptions of a sample of the projects I have led from the professional to the whimsical.

| |

| |

| Solar Garage In my last year at work I was on a reduced 3-day week. That meant I had 4-day weekends to spend building a new garage. The point was to build a garage that was optimized for a large solar system. I tore down the 70-year old single garage in August and finished the new garage in late November of 2019. There is 10 kW of solar on the roof of this garage. | |

| |

| Geosynthetics Training My final project at work was to put together a comprehensive online training program in geosynthetics for internal product training. The project took 16 months from proposal until completetion. Working with the other divisions in the company I guided the selection of the iSpring learning software for course authoring and content delivery. Then I wrote and narrated 95 courses in geosynthetics. I finished the last course on March 13th 2020 as the company shut down for the pandemic. I understand that the courses were deployed to many of the staff as they worked from home. | |

| |

| Grid Tied Solar Panels In the fall of 2010 the City offered a subsidy of $3 per watt for grid tied solar. I jumped at the chance and by the end of the year had 1540 watts of solar panels installed. Getting the project done under time deadlines was quite difficult. | |

| |

| Gas Collection Floating Covers One of my projects at Layfield was to develop a new design for a floating cover for manure lagoons that will capture methane gas. The project included designing a cover to fit our manufacturing strengths, applying for patents, and developing the markets in both the US and Canada. | |

| |

| Geothermal Heating Updgrade In 2005 we completed a major upgrade to the mechanical and electrical systems in our house. Part of that was to add geothermal heat (a ground source heat pump). We improved our "Energuide" rating on our house from 31 to 79 which, according to our engineer, is the largest increase he had seen. | |

| |

| Layfield Plant Managment Transition In 2004 I accepted a 2-year term position as plant manager to make the transition from the 22-year retiring manager to a new management team. In two years I was able to slash paperwork, revolutionize communication, and buy two pieces of automated equipment. At the completion of my term the acceptance of my young assistant as plant manager was taken without comment and the plant workers were independently managing their time to meet plant objectives. | |

| |

| Unitarian Church of Edmonton Project Manager Our church purchased an old warehouse that was to be renovated into a new church building. As project manager I led the project over a two year period. I personally took care of the difficult zoning and permitting. I also led the volunteer work parties that completed the demolition (including the removal and marking of kilometers of abandoned electrical/networking circuits), renovated tennant space, and took on weekend projects such as all computer wiring. I managed this $800,000 contract through to completion and brought the project in 10% under budget. | |

| |

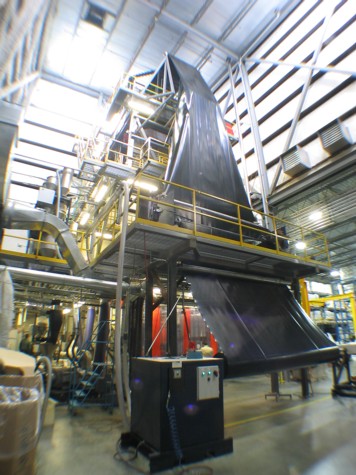

| Enviro Liner Manufacturing For many years at Layfield we have wanted our Poly Films plant to make one of the geomembrane materials for our division; however, political infighting prevented success for over 10 years. Finally my lobbying efforts were successful and the owner stepped in and gave me the go ahead and support I needed for this project. Within three months we had successfully completed trials, and within six months the product was on the market. One year later the Enviro Liner product line had become the highest volume product of the Poly Films plant and went on to provide the largest profit contribution of any product in the company's product line. | |

| |

| Layfield Product Binder and Web Site I started preparing our technical product binder since 1988. Early on it consisted of photocopies of suppliers spec sheets. I decided in the early 90's that we should move to selling the Layfield brand and started producing Layfield-branded specs. That led to detailed descriptions of our products; then descriptions of the applications where our products were used. In 1996 I created the first Layfield web site; hand coded from the product binder write-ups I had built. In 2000 I led the project to set up a database driven web site. After a lot of effort that site was set up so that users can print product binder pages directly from the web site. The web site and the product binder displayed the same information making information management and version control much easier. | |

| |

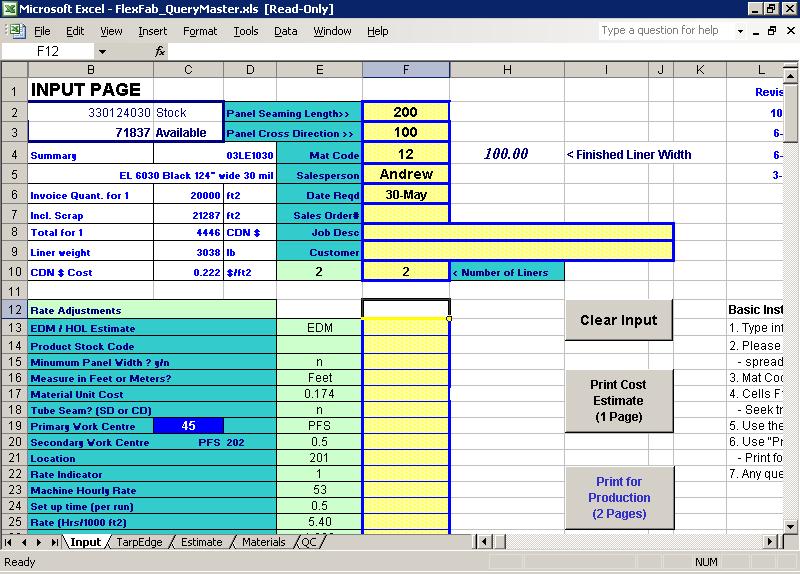

| FlexFab Fabrication Estimating Tool In the early days of my sales career at Layfield it was difficult to get estimates for the basic geomembranes that we sold. After analysing what went in to making an estimate I came up with a spreadsheet in 1993 that completed estimates for our basic products. Each year I would update this spreadsheet and add new features until it became the standard across the company. This spreadsheet handled about 80% of all current fabrication estimates, it printed a saleman's summary, the shop work order, and the shop QC testing forms for each order. It prepared estimates for over 100 materials, incorporated different rates for our two fabrication shops, checked for the most efficient fabrication method, provided US and Canadian pricing, and showed how much material was in stock. Users needed only enter the length, the width, and material type to get an instant estimate. When I retired in 2020 the FlexFab tool was still being used. | |

| |

| The Tower of Power When my wife and I first got married we lived in a very small rental house (500 ft2). Space was at a premium and it was difficult for her to get all of her things int our bedroom. After assessing what she needed available in the mornings I built a special make-up tower. This tower holds all her make-up, her ear-rings, and hair care products. It can spin 360 degrees and has plug-ins for hair dryers, drawers for make-up, lots of storage, dimmable lights, a CD player, and a full length mirror. When we moved to our current house I had to shorten it by 6". A few years later I removed the tape player (shown) and put in a CD player. The Tower of Power even passed an electrical inspection by an incredulous inspector. | |

| |

| 418 Squadron Training Resources During the years when I was an aircraft maintenance instructor in 418 Squadron (air reserve) we were often faced with a lack of training resources. Our part-time training schedule made it difficult get much hands-on training. We came up with an idea for a training weekend at CFB Cold Lake where our trainees would get access to fighter aircraft and advanced training resources. We set up an annual training weekend where our trainees were instructed on fighters by the training staff in Cold Lake. This weekend really helped let our students see what they had learned in the classroom and was a very popular trip. Once we got this trip started it became an annual event. | |

| |

| Newtonian Telescope Construction I am very interested in astronomy and took a course with a friend that taught us how to make a simple telescope. Within the year we had finished her telescope but I kept fiddling and trying out new things. It's now been over 15 years since I started on my telescope and I have experimented with hundreds of ideas. Each night as I lie in bed trying to shut off the day's events I think about my telescope. The complexity of the telescope project clears my mind of the day's stresses and I fall asleep. This is one project I may never want to complete. | |

| |

| Coffee, Sofa, and End Tables When we moved into our house in 1994 we needed lots of new furniture. I thought I could build our own coffee tables. They turned out great. So good in fact that I had other friends ask for sets. Eventually I made four complete sets. Here is a picture I took before delivering one set. The completed tables in the background include the sofa table, two end tables, and a coffee table. In the foreground is a complete set of the same tables packed for shipment to my friend. After many years of use the tables are still holding up really well. | |

| |

| Car Computer Stand I bought my first "laptop" computer in 1989 and found that at a little over 30 pounds it was difficult to use in many situations. As a salesman I wanted to use my laptop in the car but found that it was very awkward. I designed and built this stand to allow me to use my laptop in either the driver's or passenger's seat. It had a sturdy lock, a sewn fabric cover to match my seats, an in-car charger, and the entire unit bolted to the existing passenger seat bolts so that no damage was done to the car. Those were the old days; the laptop I use now weighs 4 pounds and I can use it anywhere. | |

|

Navigation

| |