|

|

| Eco-Solar Home Tour 2023 How Does a Net-Zero Energy Home Work?

As the organizer of the Eco-Solar Home Tour I have seen how net-zero energy (NZE) homes have been developed over the past few years. Most builders are including some common design elements into their NZE homes. This article outlines these current features as of 2023. Click on the picture or here for the complete article in PDF format.

|

|

|

|

|

Geosynthetics 2019 Long-term Performance of HDPE Geomembranes Exposed to a High Temperature Brine Solution

This is the fourth technical paper on the HEATGARD geomembrane. The results of the hot brine testing were not as definative as the testing for the chlorine or the oven aging but they are presented in this paper.

Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geosynthetics 2017 (Chile) A new geomembrane for chlorinated water

containment

This is the third technical paper on the HEATGARD geomembrane. At the same time as we were doing the oven aging testing we were also exposing the geomembrane samples to chlorinated water and brine. This paper discusses the results of the chlorinated water exposure. We also did testing with calcium depleted water and got excellent results. This paper was presented at a conference in Chile as a way to raise our profile in South America. Unfortunately I didn't get to go to Chile to present the paper! Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geotechnical Frontiers (Geo '17) Automation of Large-Scale Geotextile and

Geomembrane Fabrication

In the CGS 2011 conference we detailed the capping of a tailings pond with high strength geotextile. As part of that project we developed a machine that could sew or weld 5 strips of material to automate the fabrication process. This technical paper outlines the development of that machine.

Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geotechnical Frontiers (Geo '17) Long-term Performance of HDPE Geomembranes Exposed to High Service

Temperature

The is the second technical paper on the PE-RT resin geomembranes. In this paper we oven aged the geomembrane samples over a period of 2 years. The new PE-RT resin geomembrane did substantially better that previously available materials. That material was then tradenamed as the HEATGARD HDPE geomembrane. Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Canadian Geotechnical Conference 2016 Tensile resistance of geomembranes for high temperature applications

In 2013 we started investigating a new type of resin for geomembrane called the PE-RT or polyethylene for raised temperature. This was the first paper published on geomembrane made from this new material that compared the tensile strength at elevated temperatures to other material types.

Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Canadian Geotechnical Conference 2015 The Practical Limits of Cold Temperature Geomembrane Installation in Northern Canada

During a winter liner installation near Prince George BC we had some problems with the liner cracking in the cold. Since the liner was not supposed to crack even down to -40C we were surprised. This technical paper covers the investigation into why the liner cracked and set a low temperature limit for winter installations. Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Hydroprocess 2015 Emerging applications for floating covers in the mining and energy sectors

This technical paper was done to try and raise awareness of floating covers that could be used in mining applications. By setting this up in a case history format we are able to show the different applications without being too commercial.

Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geosynthetics 2015 Geomembrane Performance Testing - Impacts of a Negative Langelier Saturation Index on Geomembranes

Another problem relates to water that is treated with reverse osmosis (RO). This is a common water treatment method in Australia as water there is quite scarce. The problem is that RO strips all the calcium ions out of the water and then the water becomes very corrosive. Calcium depleted water was damaging our liners and we had to investigate and test materials to try and see what was going on.

Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geosynthetics 2015 Geomembrane Resistance to Hot Brine in Produced Water and Flowback Applications

As we did more work in Australia we kept running into hotter and hotter containment applications. In some parts of Australia the summertime temperatures will go above 45C and the liners they were using were not holding up. We did a series of tests to see how our particular materials would hold up in a hot brine enviroment and wrote up the results in this technical paper.

Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geosynthetics 2013 Upper Chiquita Reservoir Floating Cover and Liner

This is a case history on a floating cover in Southern California that shows how they build new water infrastructure. A very big project, with a number of unique problems along the way. Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geosynthetics 2013 A Unique Camouflage Floating Cover

This was a really interesting project in California where we couldn't put a floating cover on a reservoir until all the neighbors agreed on the colour of the floating cover. An interesting exercise in working with the neighbors.

Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Canadian Geotechnical Conference 2012 Case study: Performance of rapid response flood control systems during 2011 flood in Manitoba

We had done a lot of work with the province of Manitoba supplying water-filled Aqua Dams for flood control. In this technical paper we outlined a new idea of trailers that were packaged with dams. These trailers were staged all over the province for flood control response. I did not actually write this paper but directed my employee on how to prepare and write his first technical paper and edited it considerably. Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Canadian Geotechnical Conference 2011 High Strength Woven Geotextiles on an Oil Sands Tailings Pond Closure

A lot of people are concerned that the Oil Sands are not being cleaned up as quickly as they would like. Part of the problem is the scale of the problem. We were fortunate to be involved in Suncor's attempt to cap their tailings pond #5. This paper details the first year of work when a lot of the techniques were invented. This project worked out to be the largest geosynthetics project in Canadian history with 3 million m2 of high strength geotextile (our part of the work), a similar quantity of geogrid, 40 km of drainage pipe, and 20 million lineal meters of wick drain. Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geosynthetics 2011 The effects of chlorine on very low density thermoplastic olefins

Over a 3 year period we experienced liner failures in drinking water tanks in Australia that were very difficult to track down. I had to invent a new test that duplicated the failure mode (which turned out to be chlorine oxidation) and then test each ingredient to determine what was going wrong. This paper details the development of the test method and the testing we did to verify that the method was showing accurate results. Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geosynthetics 2011 The Development of Small Fabricated Geomembrane Biogas Covers

Animal manure is thought to be a developing source for biogas collection. Unfortunately the most common type of manure containment is not suited to having a cover installed to collect the biogas. This paper details the development of a small prefabricated biogas cover that is designed to address the problems associated with covering animal manure ponds with a high solids content (slurry storage ponds). Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Canadian Geotechnical Conference 2010 A Case History on a Challenging Encapsulated Geomembrane Containment System for a Lime Sludge Pond Facility

Stat Oil Hydro is the Norwegian national oil company and they decided to participate in the Alberta oil sands. Since they didn't know the Canadian market they asked us to assist them. We ended up working as the general contractor and did a lot of the design work for their on-site containments. This paper captured the case history. Click on the logo or here for the complete paper in PDF format.

|

|

|

|

| Geosynthetics '09 Long-Term Weathering Stability and Warranty Implications for Thin Film Geomembranes

In order to differentiate our geomembrane products we started on a program to develop outstanding UV properties. In our flagship geomembrane material we added specific UV additives that were the best in class and then started testing. We eventually completed 30,000 hours of accelerated UV testing when no other company had completed more than 16,000 hours. The excellent UV performance let us extend warranties out to 25 years. This paper covers the research done and the reasoning behind the warranty. Click on the logo or here for the complete paper in PDF format.

|

|

|

|

| Canadian Geotechnical Conference 2008 Development of high temperature resistant geomembranes for oil sands secondary containments

For a number of years we had been doing research with our oil sands clients on secondary containment liners for underneath large heated storage tanks. The heat under the tank would "cook" most normal liner materials. We had to develop and test new types of materials that would withstand the temperature over the long term. This technical paper was the result. Click on the logo or here for the complete paper in PDF format.

|

|

|

|

| Geosynthetics Magazine Article The Wrigley Reservoir and Fire

Sometimes a story writes itself. In this case a wild fire swept over Catalina Island in California and went right over a reservoir we had just finished building. The reservoir had a floating cover and we were hired to go in after the fire to clean the cover and look for damage. The cover did really well with almost no damage. If you read only one story on this page then I suggest you pick this one. Click on the logo or here for the complete article in PDF format.

|

|

|

|

| Mitigating Air Emissions Conference 2008 A new geosynthetic cover for odor control and biogas collection

We had been working on a biogas cover for about a year when this conference came along. I had been an invited speaker at workshops that Iowa State was giving on manure covers and they asked if I could present my research. This was the first of two papers on our new biogas cover. This one was focused on reducing air emisions. Click on the logo or here for the complete paper in PDF format.

|

|

|

|

Layfield Technical Binder and Web Site

Since 1988 I have been maintaining and writing the Layfield binder content, creating brochures, and arranging printing. In 2009 we printed 1500 binders and 1000 partial binders. The binder was the primary sales tool for the Layfield sales force. In 2001 the web site was integrated with the binder so that all the black and white technical pages in the binders were printed directly from the web site using a special "catalog print" function. I led the project to develop web-based printing which largely eliminated issues with version control.

|

|

|

|

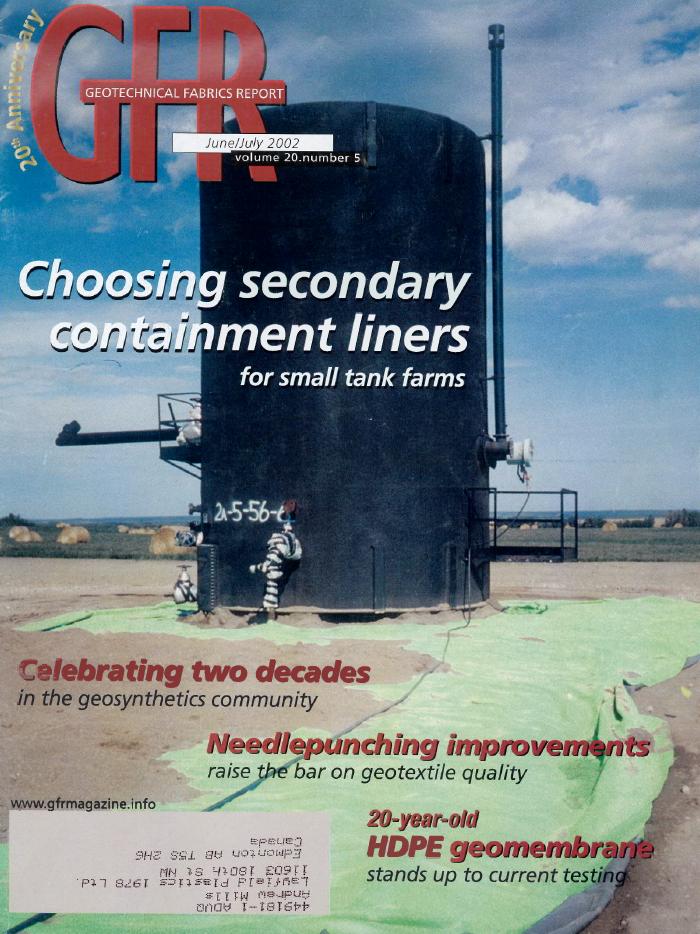

| June/July 2002 Geotechnical Fabrics Report Choosing Secondary Containment Liners for Small Tank Farms

This cover story in the June/July issue of Geotechnical Fabrics Report is a discussion of how to select liners for small tank farms. Most engineering discussion to date had been on large projects; but most of the real work is in small tank farms. The cover photo shows a typical oil tank going in near Llyodminster. Click on the picture or here for the complete article in PDF format.

|

|

|

|

| 52nd Canadian Geotechnical Conference Geomembrane Use in a Landfill Cap Rehabilitation

This technical paper in the 1999 Canadian Geotechnical Conference talks about our assistance to the City of Edmonton in correcting drainage problems at an old landfill. We built a canal across the top of the landfill to drain away a pond that was allowing water to seep into the waste. Rich Hoffart was the salesman that sold the project and helped to install the liner. I also did the web site for this conference. Click on the picture or here for the complete article in PDF format.

|

|

|

|

| 51st Canadian Geotechnical Conference

Performance of an Exposed HDPE Pulp Mill Pond Liner After 10 Years

My first job at Layfield was as a welding technician on this project in Whitecourt Alberta. At the 10 year mark I went back and did an investigation of the pond and how the material was performing. We have since gone back at the 15 year mark and at the 20 year mark and the liner is still doing fine. I wrote this paper to summarize how an early HDPE liner material was holding up. I was on the committee for this conference and designed and arranged the printing. I designed the covers for the conference proceedings, the conference program, and organized all the printing. I also created and maintained the conference web site. Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geosynthetics '97

Temperature Corrected Tensile Strengths for Geomembrane Field Seams

We ran into trouble on a job site where we couldn't meet our published tensile strengths. Investigation showed that on a very hot day the tensile tests would not meet spec. This paper started out as a way of calibrating our tensile testers for extremes of heat and cold. The cold room was a research freezer at a local engineering firm; but, the heated room was the sauna at our local public swimming pool - after each test we jumped into the pool to cool off! We still use this calibration on jobs that need testing on very hot days. Jason Stang was a summer student and completed a lot of the testing. Click on the picture or here for the complete article in PDF format.

|

|

|

|

| Geosynthetics '93

Geomembranes for the Containment of Sulphur:

A Case History

This was the first technical paper prepared at Layfield for a peer-reviewed technical conference. It is a case history where we worked with Shell Canada to develop the use of liners to protect groundwater under sulphur storage blocks. In the past these blocks were placed on clay but seepage was a problem. We had to determine if there was a liner that would work. Fortunately Shell was able to hire us to do the investigation so we were able to do quite a bit of work. I was the lead investigator and arranged or completed all the testing. Since this job we have completed many sulphur block liners across Canada and are currently bidding on a project in Kazahkstan. You'll notice I use the spelling "sulfur" in the paper, the organizing committee required American spelling for all papers submitted (but missed it in the title). Click on the picture or here for the complete article in PDF format.

|

|

|

Home, Resumé, Projects, Publications, Patents,

Skills, Interests

|