Patents

Here are some of the patents that I have been involved with. Most of these are my ideas where I then worked with other people to finish the development. Usually the beginning of the idea would be an issue with a competitor or a competitor's product. I learned a lot about patents. In the early days we had a great deal of difficulty getting our patents approved. I have since learned that there is lot to how you structure your application. You can pack the application with additional items that you can use as the examiner pushes back.

My experience with the US patent office is that they were very confrontational. Their first answer is always no. They always argue that any person "skilled in the art" would have been able to put together a similar idea. Often the back and forth would go on for so long that the patent wasn't worthwhile anymore as the business had passed it by. The Canadian patent office was much easier, in a couple of cases they approved the patent quickly and with very little comment.

In the last couple of years I seemed to find the right method to get a patent approved. We got both the Fluid Fillable Structure and the Floating Cover with Structural Supports approved in Canada in only a few months. The conductive geotextile we managed to wrangle through the US office in less than a year which is pretty remarkable.

Anyway, here are the ideas that I managed to get on paper. Some went through to patent and some got stalled. A few even went on to become profitable products.

The story of how we learned how to obtain patents starts at the bottom of this page and works to the top. At first we had a lot of trouble getting patents, however, we eventually learned how to structure the patent applications for success.

| |

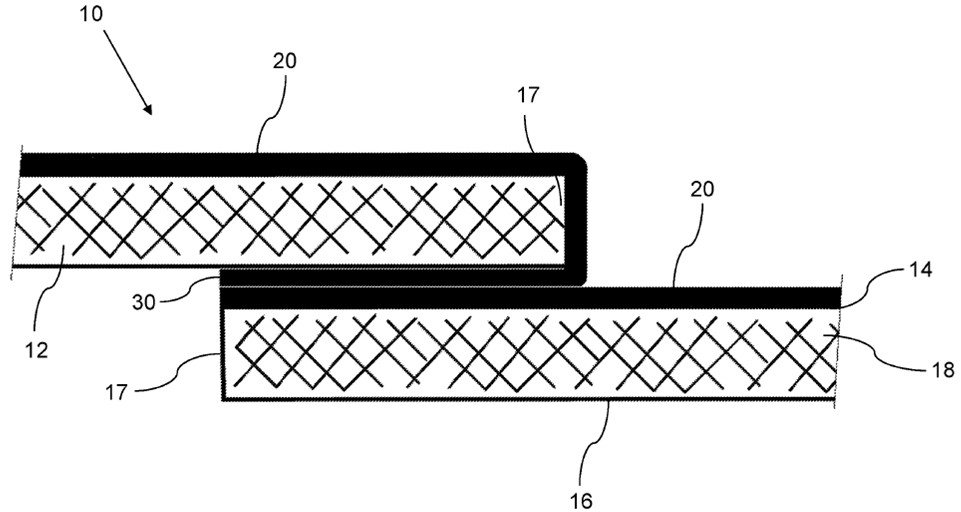

| Conductive Geotextile US10488293B1 2019-11-26 By this point we've learned our lessons with patents. This last patent is for a conductive geotextile that is a combination of a conductive polyethylene film and a non-woven geotextile. We were pretty sure we would have a hard time getting this one through the patent office so we started in the US as that was where we actually needed the patent (Canada is a small market). On this application we used all of the skills we had learned to structure the patent in a way that we could address the examiner's objections. It worked. We got our US patent in less that a year. Applications have been made in Canada, Australia, and a worldwide PCT has been filed that will allow this patent to be applied for in most other countries. I finished this project just before I retired so it will be interesting to see how far this idea goes in the furture. The conductive geotextile is being called GeoVolt. | |

| |

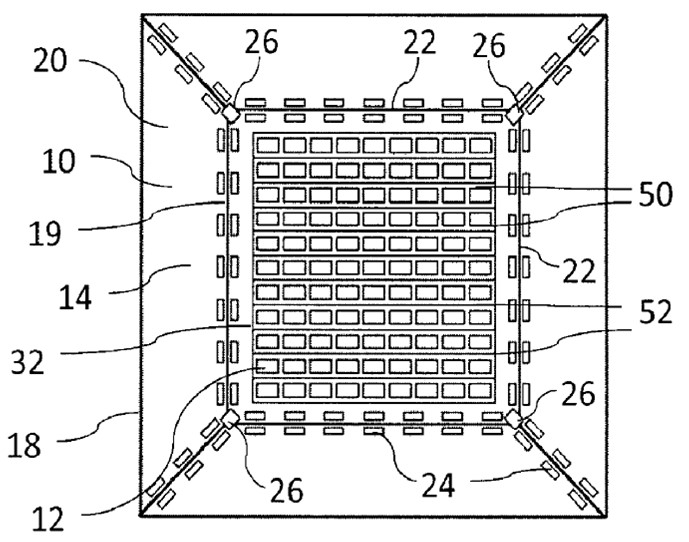

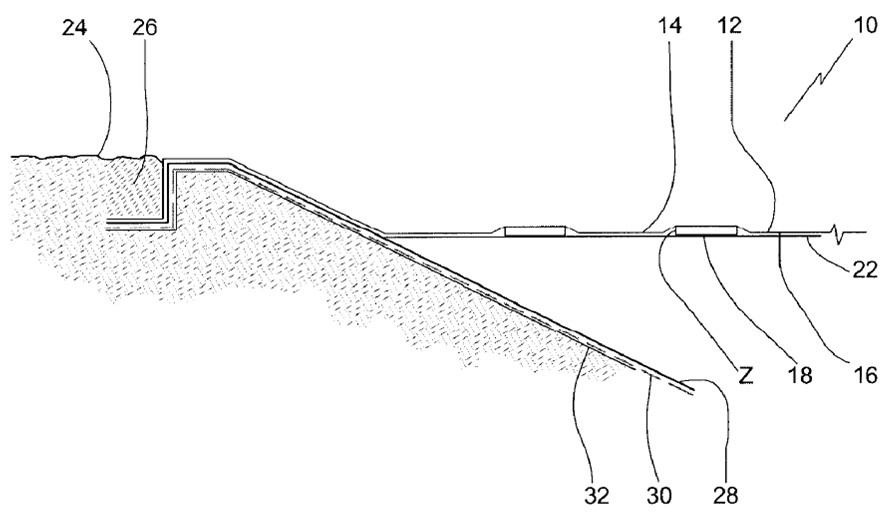

| Floating Cover with structural supports CA2941453A1 2017-06-20 For the last couple of years of my career I was given the chance to try and get floating solar started. That was a lot of fun. Part of the focus for floating solar was to put solar on to floating covers. There were a couple of solar cover patents and hundreds of solar patents happening every year. We felt that if we tried to get a patent that focused on solar we would be shot down pretty quickly. So this patent is focussed on the floats and frame that would be needed to support "something like" solar panels. Look closely at the patent and you will see solar mentioned only once in the claims. That was done on purpose to downplay the purpose of this patent. We got the patent in Canada very quickly but floating solar did not get going so the US patent application was abandoned when I retired. | |

| |

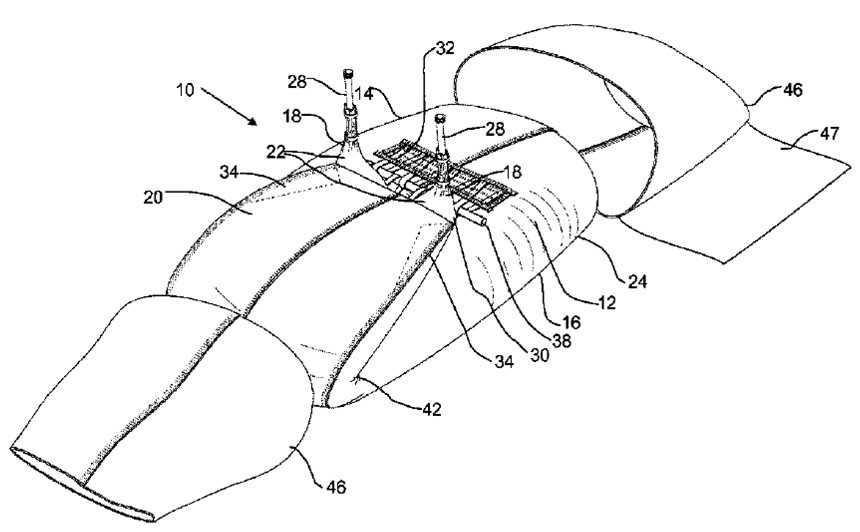

| Fluid Fillable Structure CA2766103C 2013-03-12 US9297133B2 2016-03-29 AU2013200015B2 2016-03-17 This is a patent for a flood control dam made with geotextile and plastic tubing. We were manufacturing these dams for the original inventor (Aqua Dam) and came up with an idea for a variation on those dams. The original Aqua Dams needed to have a high point of ground to start on so that you could hold the open ends of the tube up to keep the water in. This new design was free-standing. By folding one end back onto the dam it could be filled on level ground. This worked much better for flood control. This dam is now the standard for Aqua Dam flood control in Canada. We got the Canadian patent in only a few months but had to fight for 4 years to get this one in the US. You will see two US patent numbers. We accepted a lesser version of the patent to break the deadlock with the US patent office and then filed a continuation to get the rest of the claims we had asked for originally. Eventually we got what we wanted. | |

| |

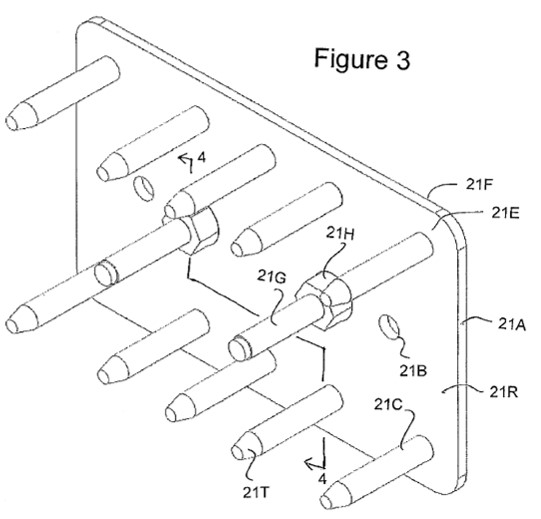

| Method of assembling and disassembling a storage tank CA 2818311C2013-11-18 US 9315318B2 2016-04-19 We were working with Westeel to come up with a water tank to hold water for oilfield applications. The problem with the Westeel type tanks was that they need a lot of nuts and bolts to hold them together. Each joint requires more than a dozen bolts. I looked at the problem and figured that I could combine all the bolts onto a plate so that you only had to fasten two nuts to hold a dozen bolts in place. We called this the "speed plate." Since Westeel was our partner I gave them this idea and they went and got it patented in Canada, the US, and Australia. The plates worked really well but cost a bit too much to manufacture and they did not become popular in the market. They forgot to name me as inventor in Canada but included me in the US patent. The plate with the pins was entirely my idea but they did the structural design. | |

| |

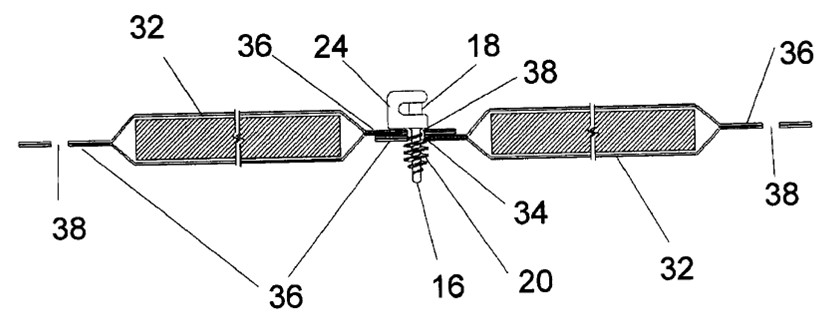

| Method of and apparatus for connecting floating covers CA2593460C 2012-01-03 US 7793390B2 2010-09-14 This is the next part of the pond cover fastener design patent. This is the patent for the actual method of joining these floating covers. We had designed this special pin that was used to screw together the insulated floating cover sections. Then a cable would secure the pins to prevent them from turning and to hold the cover on the water surface. We got this patent but our field crews didn't like the pins and wouldn't spend the time to make them work. They wanted to use the attachment method that our competitors used which was patented. In the end we pretty much stopped selling these types of covers for a number of years until the competitor's attachment patent expired and then used their method. | |

| |

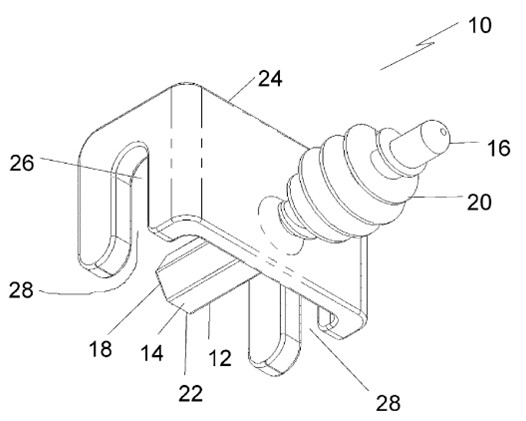

| Pond Cover Fastener CA 120801S 2008-07-22 USD 585729S1 2009-02-03 This is an unusual type of patent called a design patent. This is where you protect the shape and form of a design. Design patents are much easier to get but not that useful as even a small change to the shape can beat the patent. We thought that this pin was unusual enough to warrant this design patent. It ended up that this pin did not get used and the patents were abandoned. | |

| |

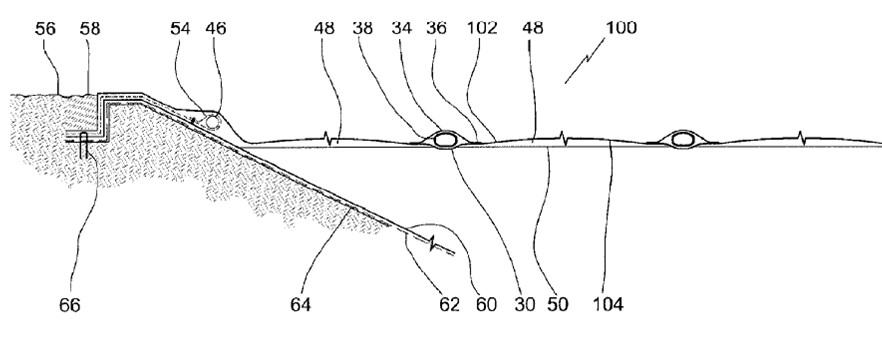

| Method of securing elongated objects to a floating cover CA 2,635,626 A1 Application US20080314901A1 Application When we were working on the evaporation control cover I came up with two methods for adding floats. One was welding the floats to the underside of the cover and the other was to make a pocket in the cover. The pocket could be used to carry either floats or weights (elongated objects). This could be used to make an evaporation cover with floats, or a biogas cover if you used weights. The two patents were filed separately and this one was focussed on making biogas covers with weights. We kept after these applications for many years but eventually it became clear they would not go anywhere and they were abandoned. | |

| |

| Evaporation Retarding Cover US 20080317551 A1 Application After the tarpaulin patent we tried this patent for a novel type of floating cover to prevent evaporation. This one was a big battle with the patent office from the beginning and never did make it all the way to becoming a patent. We were new to patents yet and I just don't think we knew enough at this point to create the application in a way that would be successful. I still think that welding foam directly to the underside of the floating cover was a unique method but the patent office disagreed. | |

| |

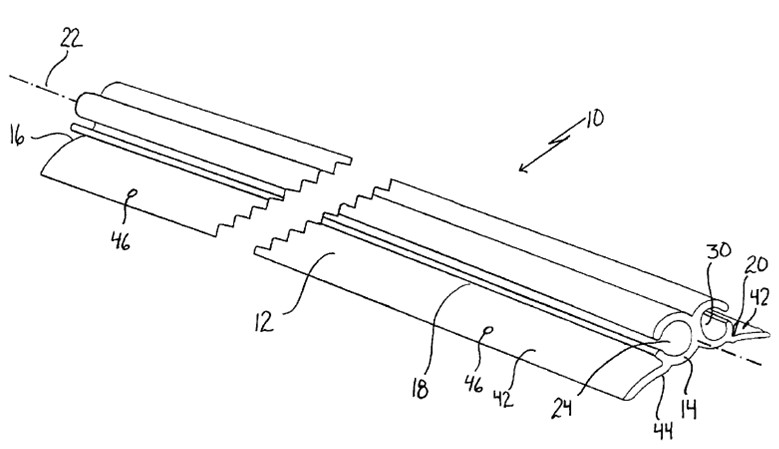

| Tarpaulin Fastener CA 2,359,515 2007-07-03 Layfield had always made a tarpaulin system that was fastened with pins. Then a company in the US came up with a system that slid the tarps into tracks. We decided to come up with a competitive system to that track-based system. This was the result. The plastic extrusion held on to rope hems that could be slipped into the tracks. The "wings" on either side of the tracks were curved to match the curve of a particular type of scaffolding that is very popular. This was the first patent I was involved with. We got the patent in Canada but could not overcome the objections from the patent examiners in the US and did not get a US patent. | |

|

Navigation

| |